|

The following describes my first hand experience with the Electromotive

JFI fuel injection kit in

1996. The kit was purchased for a '90 Jeep YJ equipped

with an AMC 258 I6 engine. My hopes (also) were to cure all the off-road

problems that occur with carburetors: flooding, rough idle, hard starting

on hills, stalling, etc.. The following describes the kit, installation,

adjustments, and issues for the Electromotive product. |

|

| Index

|

|

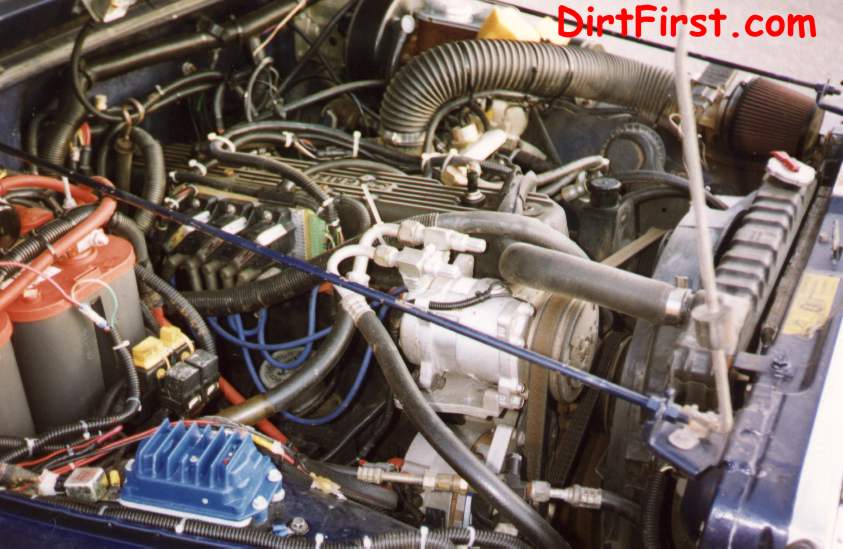

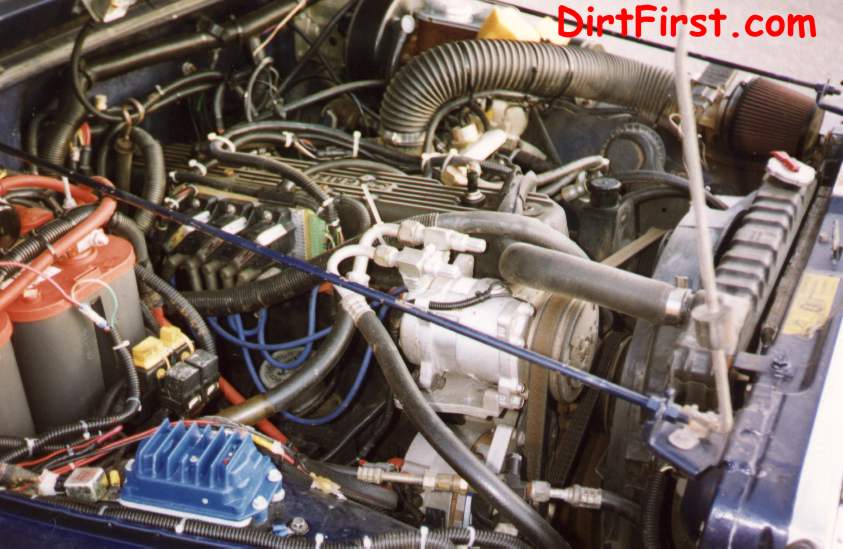

JFI

Kit installed on 1990 YJ |

|

The Kit

Purchasing the kit is the

easy part. All you need is a local dealer or you can order direct. I ordered

direct. The kit is very complete, "I was impressed". Just about

every thing you need to install the product is included with the exception

of fuel line and some small parts.

-

Throttle body

-

Computer Module

-

Fuel Pump

-

Wiring harness

-

Direct fire ignition system (no points)

-

Temperature sensor

-

O2 sensor

-

installation instructions

-

CARB EO and emission decal for under the hood

At the time I purchased the kit, it was about $1800 plus tax.

Back to top

|

|

Installation

-

The installation was relatively simple, but requires a lot of

pre-installation preparation and installation time. I read the

installation manual at least five times before opening the hood

on the Jeep. Doing so made the installation easy and it worked

correctly on the first try.

-

Also, you

must use high pressure fuel injection rubber hose, at more than a $1 a

foot, this could be a hidden cost you did not plan for. You have to remove

your gas tank to replace all existing rubber fuel lines with the good stuff.

-

The second

most difficult part of the installation was finding an appropriate location

for the fuel pump. The installation instructions require the pump to be

located at or below the bottom of the fuel tank. On a four wheel drive

like mine, this would be a mistake because it would be damaged or ripped

off by the first rock, stick or large clump of mud it came in contact with.

So, I located mine in front of the fuel tank on the inside the driver side

frame rail. This means that the pump will have to be primed all the time,

which is hard on the pump.

-

The next step was to remove the carburetor and almost every pollution control device

under the hood. The kit greatly simplifies the engine wiring and plumbing.

It is 50 state smog legal, too. Next, I bumped the engine over so number

one was at top dead center and pulled the distributor. I installed the

new trigger system in its place. I bolted the throttle body in place and

completed the plumbing. The computer mounts to the valve cover (a design

I don't care for due to heat and vibration). The computer has three direct

fire coils built into the mount. This thing really stings the spark plugs.

I finished the wiring in the engine bay. I removed the old wiring and was

left with a clean looking engine compartment. The next step is to install

the mass air flow sensor and air filter to the fenderwell. Now install

a check engine light inside the jeep (you have to buy one). I used a Linwood

Jumbo 12VDC diode and made a legend plate.

-

I completed the rest of the installation according to the manual. It took about twelve

hours to complete the installation.

-

The next step is to replace the oxygen sensor with the heated style from the kit.

Older jeeps without an O2 sensor will have to add weld a bung in the exhaust

system for the new sensor.

-

Next you need to replace the coolant temperature sender with one in the kit.

Back to top

|

|

Initial Starting and Adjustments

-

For the initial starting of the engine with the newly installed JFI kit, I verified

the throttle position sensor (TPS) for the correct volt reading with the

key set to run. When you turn the key to the run position you should

hear the electric fuel pump run for about three seconds, then shut off.

This is also typical for factory fuel injection. Since the fuel line

is not primed, I suggest that you turn the key to off and then to run again

(several times) to make sure the line has good fuel pressure (about 40

PSI). A fuel pressure gauge is necessary to test the fuel pressure.

With pressure in the fuel lines, I checked for fuel leaks before attempting

to start the engine, every thing was fine. After a short prayer,

I turned the key to start with my foot off the gas peddle, and the engine

fired easily. I was very excited!

-

The timing was adjusted and away I drove. It ran well but seemed

hot. I didn't know that a coolant sensor was bad already. I

ran the jeep a couple days but did not like how hot the exhaust manifold

seemed to be getting. I called electromotive and they said the computer

would learn the motor and that the 4.2 motors were "dirty" and

I should drive it awhile. I did, one month later on the freeway -

the engine backfired and began to stumble. I had cooked the valves

in number 1 and 6 cylinders. Read on for more details.

Please understand that these are my personal experiences with this product.

In addition, I personally know three people with the kit that have suffered

similar problems. Two of them returned to carburetion and the third

is still struggling to make it work. He says "when it works it's great,

but…."

Back to top

|

|

Fuel System

-

For a bolt on product, it is fine, but there are some overall shortcomings in

the fuel system that you should be aware of. The first thing is that my

fuel tank was not setup for fuel injection. With a carburetor, it does

not matter if the fuel pickup sucks some air from time to time because

the carburetor gets its fuel from its own built-in fuel bowl. This is not

the case with fuel injection. If the fuel pickup in the tank sucks some

air, your engine will stall. A fuel injection tank has a sump in the bottom,

which provides fuel for the fuel pickup at all times, even when you are

low on gas. Without the sump, the fuel pick will suck air when you are

low on gas, especially when going around corners and all the time when

off-road. I was running out of gas with 5 gallons still in the tank. I

also experienced vapor lock on hot days

-

The next fuel issue is the location of the fuel pump. The best location for the

fuel pump is in the fuel tank. This is where it is located on nearly all

fuel injected cars and trucks. The fuel keeps it cool, it is located right

at the fuel source eliminating the line priming problem, and it is away

from the elements that could damage it. The disadvantage is that the fuel

tank must be removed to service the fuel pump. I switched to a 1991 fuel

tank and in-tank pump for the 4.0 liter engine and my fuel pump problems

were solved.

Back to top

|

|

Electrical System

-

Your electrical system must be in excellent condition to support fuel injection. If you

have a shaky alternator, a battery that always needs to be recharged, and

a lot of old wiring that has been spliced and crimped 10 times to many,

you will not be happy with your new fuel injection kit. While you are installing

this kit it is the perfect time to clean up the old wiring and upgrade

your charging system.

I have dual Optima batteries in the Jeep and a Wrangler Power Products 160 amp alternator

and felt my power capacity was more than adequate.

Back to top

|

|

Problems

-

One problem involved the trigger assembly which failed twice and left me stranded.

I had the vehicle trailered home once and flatbedded home the second time. The sensor used

to detect crank position failed both times. Both times they were replaced

under warranty.

-

Wiring harness woes. I had wires break inside their wiring loom on one occasion,

at the mass air flow sensor once and at the computer twice. All three times killed the vehicle

immediately. Carry your schematics and a meter. I was able to repair the

wires each time. I don't know why they failed and neither did Electromotive.

-

The computer module failed three times. The jeep began to run rough and stumble at first and then

finally stopped altogether. The ECU was replaced and the problem was solved temporarily.

The next failure began as an intermittent shutdown. The jeep would just quit. Wait 10

minutes or one hour or the next day and it would run normally. Finally it failed altogether

and I had it trailered home and replaced the computer again. Problem solved temporarily.

The third time it would stumble and cut out but keep running. It happened infrequently but

seemed to happen most on the freeway. Replaced the computer again. Problem solved.

-

Another problem involves the availability of parts. Each time the system failed I had to get parts

from Electromotive or one of their reps. It meant a wait.

-

The final problem involves the sensors and the computer firmware. I had the temperature sensor

fail twice. The first time was about a month into the retrofit. The computer leaned out the

motor thinking it was cold. Guess what happens when... lean fuel supply, warm motor, freeway speed,

long uphill pull. Yep, you guessed it, cylinders 1 and 6 fried. I had to rebuild

my motor twice.

Back to top

|

|

My Jeep Today

-

Well, it has been over two and 1/2 years since I purchased the JFI system which

is no longer installed in my jeep. After the second engine rebuild

I just didn't trust it. So I sold the motor and the fuel injection

along with the old carb setup.

-

Don't get the wrong impression! After experiencing the JFI kit on its good

days, I still had a huge desire for a fuel injected Jeep. So, I installed

a "factory stock" fuel injected Chevy engine and have been very

happy ever since. It is smog legal, too! (more on this in a future article)

-

I consider this a very expensive ($5000+) and frustrating lesson and have learned

that the only way to go is to use FACTORY, FACTORY, FACTORY products that

run on thousands of cars and trucks. Parts that can be purchased

and replaced nearly anywhere. Parts that have been proven by the

test of time and designed by competent engineering.

-

At this time the only retrofit fuel injection kit I would even consider for the 258

is the "Jeep OEM" kit and it is expensive. However,

it uses the electronics and fuel system from the 1995 4.0 liter motors

(-factory parts-).

-

Update

'99

- the 5.7 liter LT1 is still running flawlessly. It was the best

thing we ever did! (looking back on it) The fuel economy

and performance are well beyond expectation. We have had no

problems at all since startup over two years ago.

Back to top

|

|

Jump to:

E-Mail us @ tech@dirtfirst.com

|